Modeling and Design Process

This section highlights how we develop our manipulator and control systems.

Parameters and Variables (Model Identification)

Identifying parameters and variables for the modeling process is very important. Our mathematical model simulations are always validated with the corresponding physical model to ensure the accuracy of the digital twin simulation when it is implemented.

Operating Points Analysis (Trajectory Tracking)

Analyzing the movement trajectory, steady-state conditions at different operating points, and stability margin are critical aspects of the plant operation. When sufficient data is available, we can train the controllers to keep the system in optimal states.

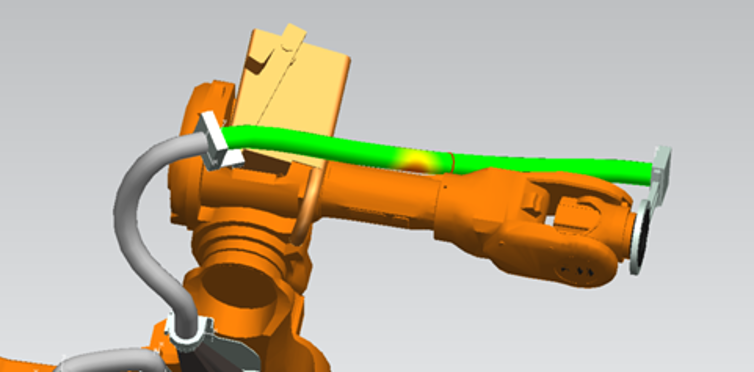

Simulation (Constrain Detection)

There are many other constraints to consider in real plant operations, such as cable deformation when manipulators are constantly in motion. Most of these constraints are built into our simulation scenarios to detect any anomalies or errors that may cause production loss.

Verification With Real-World Scenarios

This section presents practical examples that illustrate how customers successfully utilize our offerings to solve key challenges and drive meaningful improvements.

Design Process

Instantaneous steady-state conditions are calculated every time the system changes the operating point. Once sufficient operating points are computed between the minimum and maximum operating points, the stability trajectory of the system is determined to analyze the continuous dynamic system within its operating boundaries. It ensures the stability of the system at any movement of the manipulator.

Single Unit Test

Before simulating the manipulator, several other constraining sub-parts must be taken into account for considerations when applying the manipulator to the digital twin simulation, such as cable deformation while the manipulator is operating in different positions.

Error Detection & Correction

With the manipulator model, control algorithms, PLC logics, and production scenarios altogether, the complete digital twin simulation model is created and ready for commissioning.

System Upgrades Impact Test

Once the error correction process is complete, system upgrade and/or modification scenarios are created to identify the probable issue or impact caused by changes made to the existing plant.

Assembly Line Commission Test

With the manipulator model, control algorithms, PLC logics, and production scenarios altogether, the complete digital twin simulation model is created and ready for commissioning and implementation.